How Does IEC 61558 Affect Designing with Transformers and Power Supplies?

June 29, 2021 by Ron Stull - 5 Minute Read

Among the many international technical standards aimed at ensuring product quality and safety, IEC 61558 is important to engineers working with any equipment that contains a transformer or power supply.

IEC 61558 protects buyers against unsafe products and enables responsible suppliers to demonstrate adherence to accepted safety principles. Designers need to understand its principles, its scope, and how to ensure compliance. Making that commitment can ease product certification and save time in the test house.

IEC 61558 is a series of standards maintained by the IEC Technical Committee (TC) 96 – “Transformers, Reactors, Power Supply Units and Combinations Thereof”. TC96 documentation explains that the committee is concerned with “transformers and power supply units intended to allow the application of protective measures against electric shock”. It does not cover transformers intended to supply distribution networks.

Generally, the scope of IEC 61558 is limited to equipment with input voltage up to 1000 Vac and output voltage up to 1000 Vac or 1500 V ripple-free DC (roughly 1000 V x √2). The source frequency can be up to 500 Hz. Output power ratings are typically up to 25 kVA for single-phase transformers or linear power supplies (40 kVA for 3-phase) and up to 1 kVA for single-phase or 3-phase switch mode power supplies.

IEC 61558 comprises two parts:

- 61558-1 contains general specifications

- 61558-2 presents requirements for specific product types

Note that part 2 specifications may include additional or different limitations on input and output ratings. All part 1 specifications must be met unless superseded by a part 2 requirement. All products must comply with an applicable part 2.

IEC 61558 certification requires compliance with the 61558-1 general requirements and the relevant part 2. If two part 2 conditions apply, compliance with both is required.

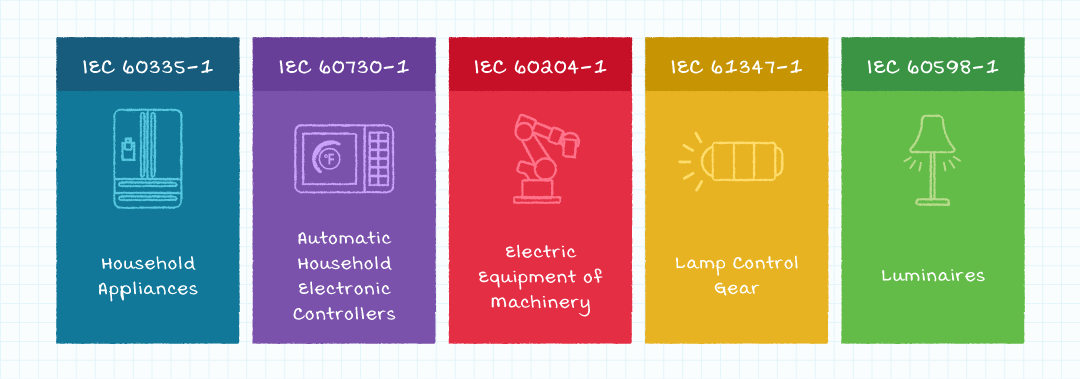

Various IEC product standards refer to 61558 as a means of ensuring the overall safety of products that contain transformers and/or power supplies. Some examples include:

- IEC 60335-1 safety of household and similar appliances

- IEC 60204-1 electrical equipment of machines

- IEC 60598-1 luminaires

- IEC 60730-1 automatic electrical controls for household and similar use

- IEC 61347-1 lamp control gear

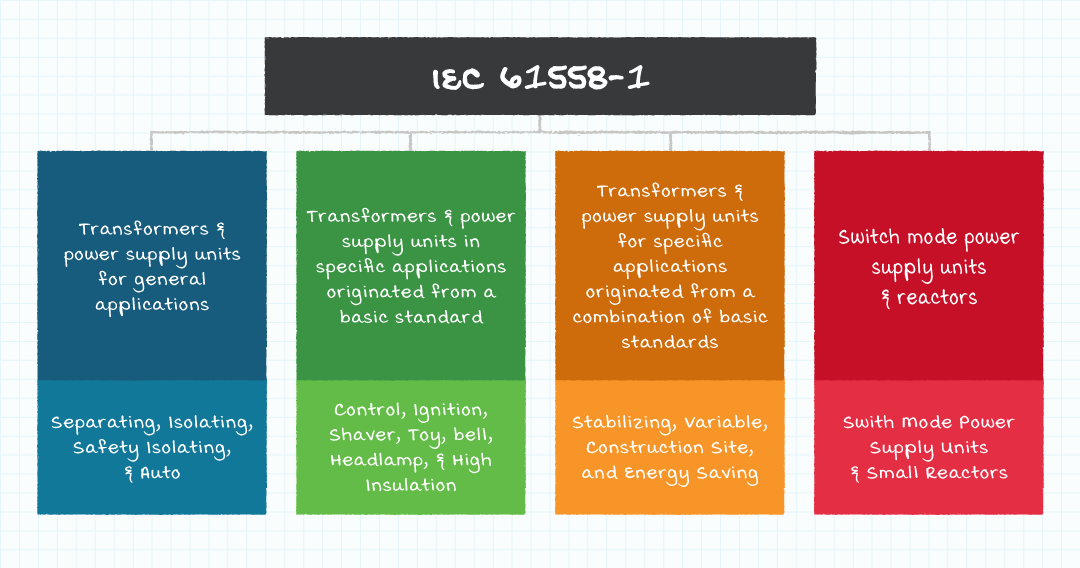

There are 18 part-2 specifications relating to various types of transformers, such as separating transformers, control transformers, isolating transformers, and product-specific applications such as transformers for use in toys, or in the ignition systems of oil and gas burners. Switch mode power supplies are covered in parts 2-16. Figure 2 shows these part-2 specifications in relation to the general IEC 61558-1 requirement.

Functional and Protective Insulation

As far as general applications for transformers and power supplies are concerned, there are certain basic standards. For example, the transformer types in the left-most group of Figure 2 are defined by the insulation system between the input windings and output windings:

- Separating transformer: transformer with input and output windings separated by at least basic insulation

- Isolating transformer: double or reinforced isolation

- Safety isolating transformer: isolating transformers designed to deliver Safety Extra-Low Voltage (SELV) or Protective Extra-Low Voltage (PELV)

- Auto transformer: no isolation

SELV is defined as a voltage lower than 50 Vac or 120 Vdc. PELV has the same parameters as SELV and also allows functional earthing.

To ensure safety for users of electrical equipment, there must be means to prevent coming into contact with dangerous voltages. Practically, this is achieved through a combination of insulation and earthing or by ensuring only low voltages are present in the system. For a deeper dive into user protection and recommended power-supply operating conditions, see our blog Insulation, Isolation, and Working Voltage.

IEC 61558 refers to three transformer classes in terms of protection:

- Class I transformer: basic insulation with the addition of an earthing terminal for connecting to the protective earthing conductor in the fixed wiring of the installation to prevent accessible conductive parts from becoming live if the basic insulation fails.

- Class II transformer: basic insulation with additional safety precautions such as double insulation or reinforced insulation. An earthing terminal may be present but isolated from accessible surfaces.

- Class III transformer: protection against electric shock relies on source supply at or below SELV. No voltages higher than those of SELV are generated.

See our blog on the Differences Between IEC Power Supply Protection Classes for more information.

Furthermore, the standard allows for failsafe, non-short-circuit proof, and short-circuit proof transformers:

- Failsafe: unit is permanently disabled upon overload or short-circuit by the opening of a winding or interruption of input circuitry (contrary to its function).

- Non-short-circuit proof: overload/short-circuit conditions made safe by external protection not provided but required via marking.

- Short-circuit proof: does not exceed temperature limits during overload/short-circuit. May, or may not, rely on overcurrent protection.

Switch Mode Power Supplies

Let’s take a quick look at IEC 61558-2-16 that applies to switch mode power supplies (SMPS). To come within the scope of the specification, the SMPS will operate from a supply voltage less than 1100 Vac and source frequency 500 Hz, although the internal switching frequency can be up to 100M Hz.

The SMPS output can be up to 1000 Vac when a separating or auto transformer is used, up to 500 Vac when an isolating transformer is used, and 50 Vac when a safety isolating transformer is used. For an independent SMPS – that is, an SMPS designed to be used in other equipment without additional protection against electric shock - the no-load/rated output is not less than 50 Vac when a separating or auto transformer is used.

Applying IEC 61558

The bottom line is that anyone involved in making or using transformers and power supplies in their designs should study IEC 61558 to understand how to choose the right components for the target application.

If you are a transformer manufacturer, you must ensure that the products you place on the market are certified to IEC 61558.

If you are placing products on the market that contain a transformer (you may have designed your own power supply inside the box) or a power supply from an independent provider, you should check whether the applicable product-level safety standard requires those parts to be IEC 61558 certified.

For more information see CUI's selection of internal ac-dc power supplies certified to 61558.

Fundamentals , Safety & Compliance

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com