The Fundamentals of Trimming the Output Voltage of a Power Supply

August 18, 2020 by Bruce Rose - 6 Minute Read

In datasheets for dc output power supplies there may be specifications regarding the ability to trim the output voltage. This often raises questions related to why does the output voltage need to be adjusted, how does an external circuit adjust the voltage, and why is the voltage adjustment range limited? This blog will discuss some power supply design fundamentals and relate them to the output voltage trim operation and specifications.

What is Trimming and How is it Used?

Trimming the output voltage of a power supply simply means adjusting the voltage by a small amount. By convention, the term trimming is used for applications where the power supply has a specified nominal output voltage and the user is able to change the output voltage by about ten percent or less. Most often users are able to trim the output voltage of a power supply by adding external components, adjusting a PCB mounted potentiometer, or applying an analog or digital signal.

Power supplies with the ability to trim the output voltage are typically used for two reasons:

- Performance - Applications where a slight change in the output voltage can enhance the performance of the product

- Non-standard voltages - A non-standard output voltage is required and changing the output voltage of a standard power supply is the most efficient means to produce the required output voltage

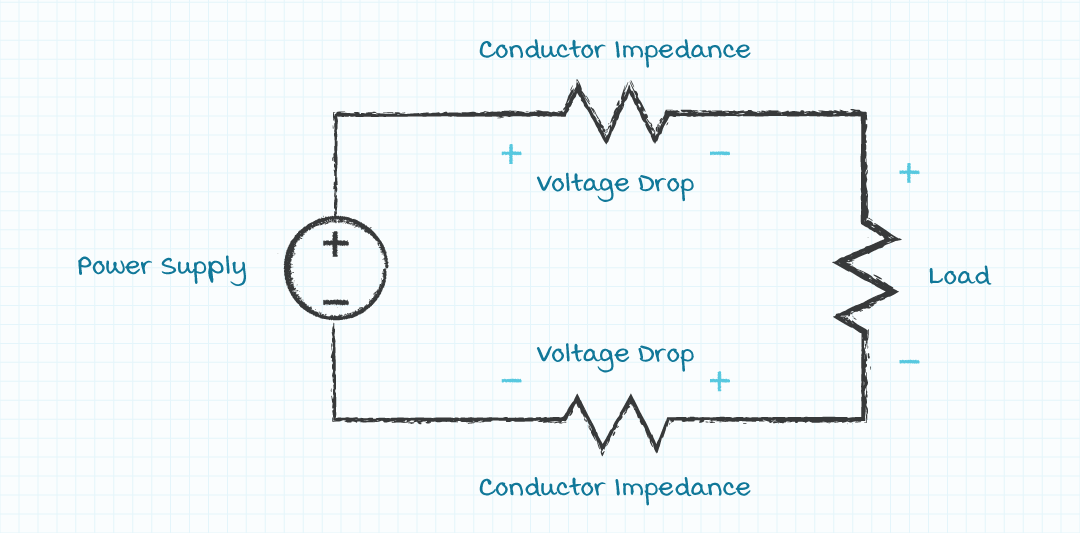

One example of enhancing performance by trimming is when there will be voltage drop along the power conductors in an application. In this case, the output voltage at the power supply terminals can be trimmed higher to compensate for the voltage drop along the conductors. Applying output voltage trimming in this application will allow the voltage at the load to be at the desired level even though there has been a voltage drop in the power delivery conductors.

power supply voltage = desired load voltage + total conductor impedance voltage drop

Some power supplies are available with the output voltage specified as a range rather than a nominal value and the output voltage can be adjustable over a ratio as great as 1:100. These types of supplies are often labeled as variable, adjustable, or laboratory power supplies. The method for controlling the output voltage in these supplies is normally an analog or digital signal or a panel mounted knob or keypad. This class of power supplies are often used when the user desires to have a single power supply which can be used in many different applications and they are not the focus of this blog post.

Trimming Methods

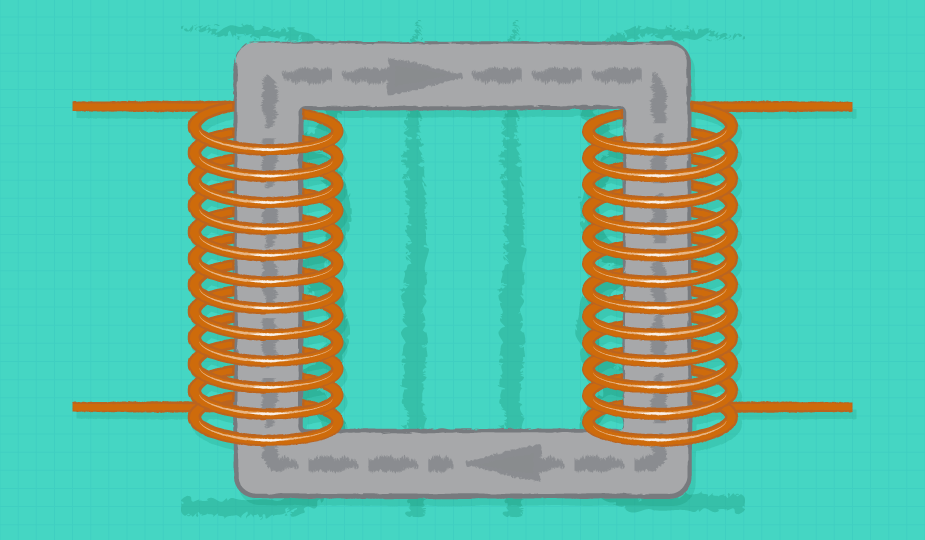

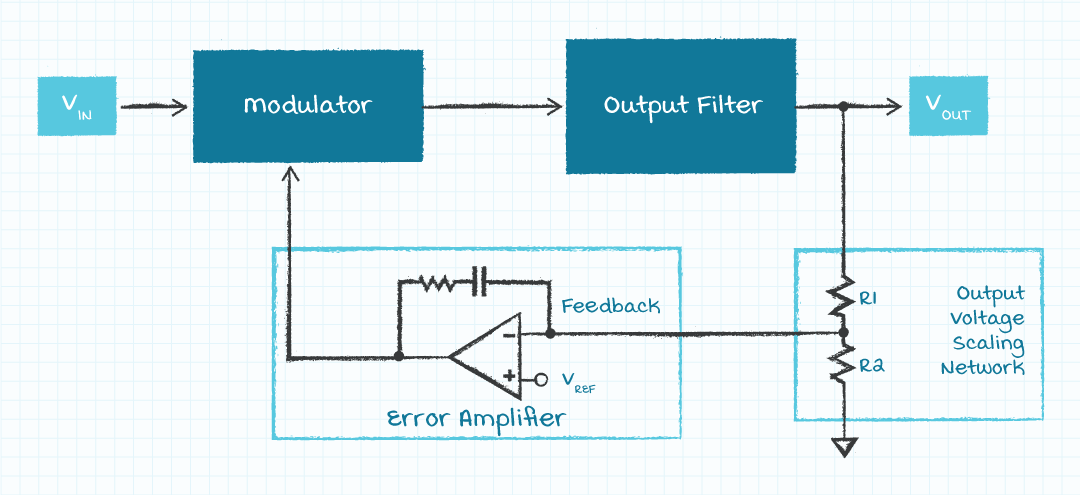

In a regulated power supply a scaled value of the output voltage is made to match a reference voltage by the use of a feedback loop. The power supply output voltage can be changed by either changing the scaling factor of the feedback voltage, injecting a trimming signal into the feedback node, or changing the reference voltage. The most common methods of trimming the output voltage of power supplies are to inject a current (a voltage source with a high output impedance) into the feedback node or to change the value of an impedance element in the feedback network. The following are methods to implement output voltage trimming in power supplies.

Applied External Resistance

The power supply design team provides a pin to the internal feedback node. A voltage source with a high output impedance can be constructed by the user placing a high impedance resistor network between the output voltage of the power supply and ground. A node of this external resistor network is then connected to the internal feedback node pin and thus injects the proper current to trim the power supply output voltage.

Potentiometer

The power supply design team places a PCB mounted potentiometer in the feedback network. The 'pot' is made available to the user to trim the power supply output voltage.

Applied External Voltage

The power supply design team provides a pin connected to an internal signal conditioning circuit which drives the internal feedback node. The user applies a trim voltage to the external pin and the signal conditioning circuit injects the required current into the feedback node to trim the output voltage.

Digital Interface

The power supply design team provides a digital interface to the user for trimming the output voltage. An internal DAC and signal conditioning convert the digital trim code to the appropriate analog voltage or current to trim the output voltage.

Trimming Limitations

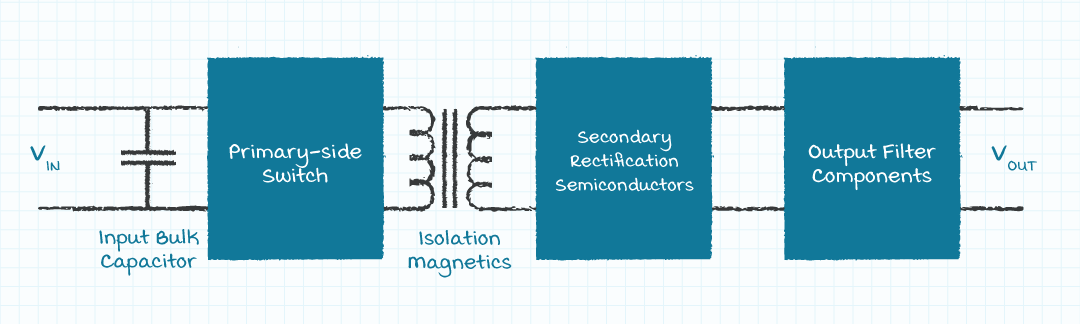

There are many possible reasons as to why output voltage trim range may be limited. Some common reasons for trim range limits include output power limits, feedback loop stability, and duty cycle limits. Trimming the output voltage may also affect the current limit of the power supply output, depending upon the topology of the power supply design. Changes to the output voltage and output current can affect the required rating of the input bulk capacitor, primary side switch, isolation magnetics, secondary rectification semiconductors, and output filter components. The cost, size, and complexity of these components in the power supply design may be increased if the output trim range is made larger.

As mentioned previously, power supplies are designed with an internal feedback loop. A change in the output voltage of a power supply can affect the loop stability of the supply. An unstable power supply loop can oscillate or latch and an overly stable loop can have a slow response time and thus provide poor output voltage regulation in the presence of load transients. Almost all modern power supply designs utilize a switching topology to reduce cost and size, and increase performance. In many switching power supply architectures changing the output voltage affects the duty cycle of the switching waveform. Both minimum and maximum limits of the switching waveform duty cycle can be encountered if the output voltage is trimmed too far.

Conclusion

The output voltage of a power supply can be trimmed to provide benefits in many applications. In most applications properly trimming the output voltage of a power supply is not an issue. However, if there are concerns or questions the CUI Technical Support team is standing by to assist our customers.

Fundamentals , Product Selection

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com