What DoE Level VII Means for Power Supply Efficiency and Your Products

October 22, 2024 by CUI Inc - 6 Minute Read

As has been mentioned in the literature, work is in progress to establish the US Department of Energy (DoE) Level VII power supply conversion efficiency requirements. Fortunately, what has also been mentioned is the changes appear to be reasonable and there is no need for alarm. In this discussion we will address why there is concern about power conversion efficiency, who should be paying attention to Level VII power conversion efficiency, and what some of the Level VII changes will be.

What Are Power Conversion Efficiency Regulations?

Electronic power supplies are often designed and selected based upon power conversion efficiency, among other characteristics. Power conversion efficiency is important to many users because the associated inefficiency appears as unintentional heat generated by the power supply. When a power supply is designed to generate less wasted heat, it can often be constructed in a smaller, lighter, and less expensive manner. In addition, lower heat generation means fewer resources are required to develop and implement methods to dissipate that heat. The US DoE is concerned regarding the efficiency of power supplies because the associated inefficiencies consume energy and thus affect the global environment. Historically, DoE power conversion efficiency requirements have been sufficiently aggressive, such that product designers and consumers rarely request external power supply conversion efficiencies to exceed them.

Equation 1: Pin = Pout + Ploss = power delivered to load + power lost as heat

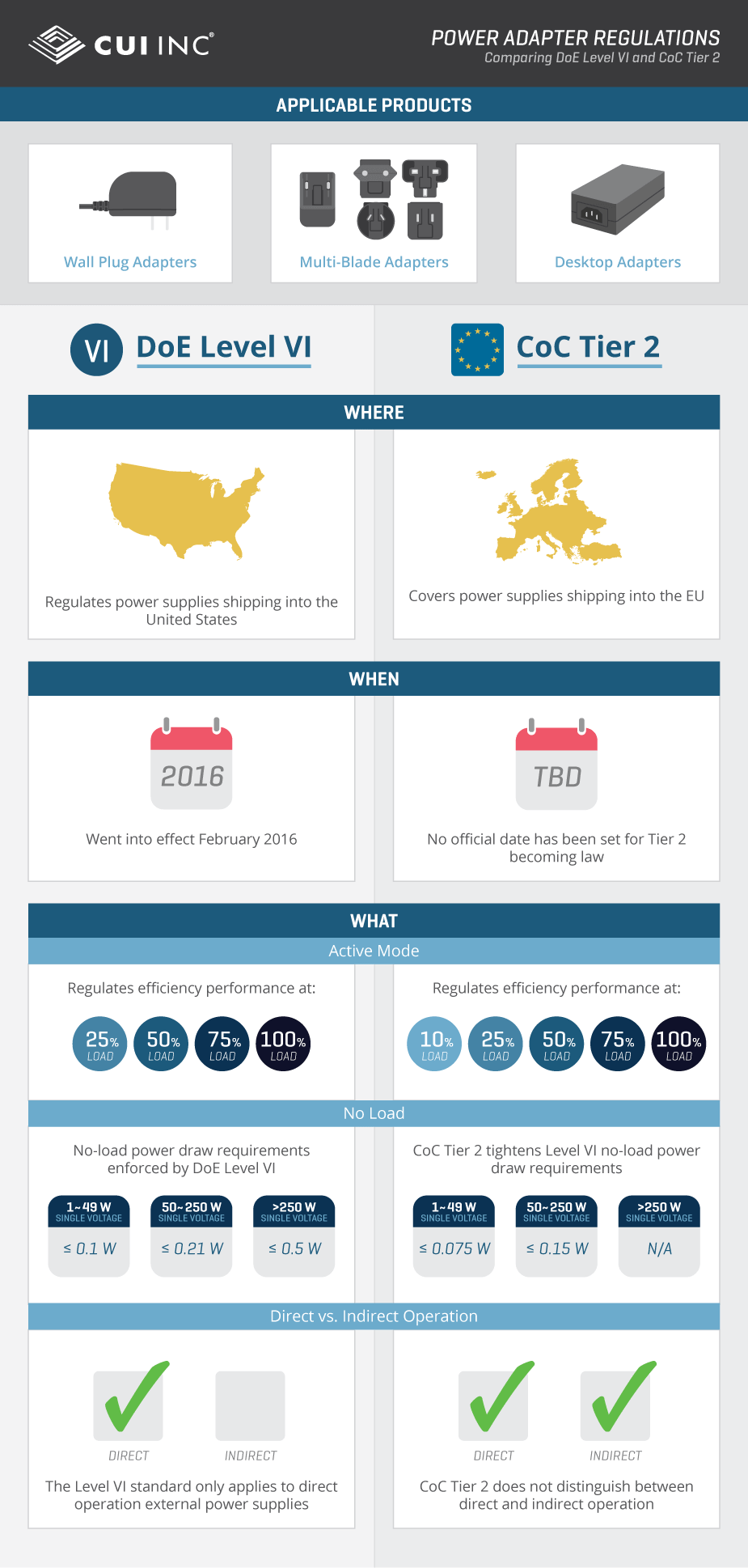

The DoE power supply conversion efficiency regulations apply to external power supplies, wall plug supplies and desktop supplies. Once the updated regulations go into effect, development teams designing products with external power supplies will have two years before new products sold in the US will be required to use external power supplies which conform to the updated specifications. During the two years after the release of the updated specifications, product development teams will be allowed to develop products incorporating power supplies meeting either the previous specifications or the updated specifications. Once those two years have expired, existing product designs will be able to continue using supplies that conform to either the older or the newer regulations, but all new product designs will need to use external power supplies meeting the updated regulations.

Pros and Cons of Adopting Level VII

Product development teams may want to continue using older power supplies in their existing products because selecting new supplies may require the products to be re-tested for regulatory conformance. On the other hand, product development teams often want to use supplies that meet the updated regulations as early as possible for new product designs. Supplies meeting the previous regulations will be older designs, sell in lower volumes going forward, and may be discontinued earlier than the more newly designed supplies. The updated DoE regulations address power conversion efficiency and should not affect the performance of external power supplies in products produced by the development teams.

Manufacturers will be able to make their own decisions regarding when they offer external supplies meeting the updated regulations and for how long they continue to offer supplies meeting the older regulations. Like the product designers, one issue facing the manufacturers is managing the schedules and fees relating to the certifications of new supply designs. It may be in the best interest of the power supply manufacturer to delay conforming to the updated regulations because the previous regulatory costs are still being amortized over the supplies being sold. Based upon past experiences, power supply manufacturers will likely offer new designs conforming to the updated regulations as soon as is practical. The manufacturers are also anticipated to offer the previous versions of the supplies beyond two years past the release of the updated regulations to continue to support older product designs.

| Basic voltage (all specifications except Vout < 6 V and Iout = 550 mA) | ||

|---|---|---|

| Nameplate output power | Minimum active mode average efficiency | Maximum no-load power |

| Pout ≤ 1 W | ≥ (0.5 x Pout) + 0.169 | ≤ 0.075 W |

| 1 W < Pout ≤ 49 W | ≥ (0.071 x ln(Pout)) - (0.00115 x Pout) + 0.67 | ≤ 0.075 W |

| 49 W < Pout > 250 W | ≥ 0.890 | ≤ 0.15 W |

| Low voltage (Vout < 6 V and Iout = 550 mA) | ||

|---|---|---|

| Nameplate output power | Minimum active mode average efficiency | Maximum no-load power |

| Pout ≤ 1 W | ≥ (0.517 x Pout) + 0.091 | ≤ 0.075 W |

| 1 W < Pout ≤ 49 W | ≥ (0.0834 x ln(Pout)) - (0.0011 x Pout) + 0.609 | ≤ 0.075 W |

| 49 W < Pout > 250 W | ≥ 0.880 | ≤ 0.15 W |

In general, end users will not need to make any decisions or do anything different when the new DoE regulations are released. The power supply manufacturers will offer appropriate products, and the product development teams will select the correct power supplies. End users making careful observations will be able to observe lower energy consumption with the products incorporating external power supplies conforming to the updated regulations.

Background on DoE Regulations

The DoE Level VII power conversion regulations were created because of the Energy Policy and Conservation Act (EPCA) and apply to external power supplies sold in the US. Regulations like the US DoE are in force in most other countries, and these regulations are ‘harmonized’ so that the same design can be economically used to meet them all. When the US DoE power conversion efficiency regulations are updated, guidelines state that they cannot be arbitrary and must meet a few basic criteria. One of the criteria is that technology required to meet the power conversion efficiency specifications must be feasible. A common measure used to determine feasibility is whether or not commercially available solutions demonstrate that level of efficiency. In addition to being commercially available, there must also be reasonable test procedures already established to evaluate the power conversion efficiency. More than just being commercially available, they must also be economically justifiable. That is to say, the benefits of the proposed standards must greatly exceed the burdens imposed. The basic goal of the DoE standards is to reduce power consumption, thus a third criteria for updated power delivery conversion efficiency requirements is that the new requirements must result in significant energy savings.

Comparing Level VI and Level VII Standards

The expected DoE Level VII regulations relevant to single output voltage ac-dc power supplies are shown in tables 1 and 2. The active mode average efficiency is calculated by averaging the active mode efficiency while operating at 25% of maximum load, 50% of maximum load, 75% of maximum load, and 100% of maximum load. Figures 1-3 show how Level VII compares to Level VI.

It may be noticed that the efficiency requirements for power supplies decrease rapidly for output power ratings of less than about 1 W. This reduction in required efficiency is due to the characteristics of switching power supplies. The two primary categories for inefficiencies in a switching power supply are switching losses and conduction losses. The switching losses are due to the operation of the power supply, are present with no load on the power supply, and increase with output current. The conduction losses are zero with no output load and increase with increased output current. Thus, at low output power levels, the switching losses are the major contributor to the power conversion inefficiency, while at high output power levels, conduction losses are most often the culprit.

The Future of DoE Compliance

The work of the DoE and other groups has been steadily increasing the standards for power conversion efficiency in external power supplies. Within the next few years, Level VII will be released as the next update of the DoE standards. Many power supply manufacturing teams, such as CUI, have already started designing to meet the new standards. Product development teams using external power supplies will be offered advanced warnings of the new requirements through many different sources before they are required to incorporate the new power supplies into their products. End customers will be automatically transitioned to products meeting the new standards and will see the benefits of reduced power consumption and the resultant improvements in environmental quality.

For more information, contact our team of experts at Bel Fuse.

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com