How Paralleling Power Supplies Affects Reliability

March 19, 2024 by Bruce Rose - 7 Minute Read

Table of Contents

- Parallel Power Supplies

- Failure Rates

- Calculating the Failure Rate of a System

- Example 1

- Example 2

- Summary

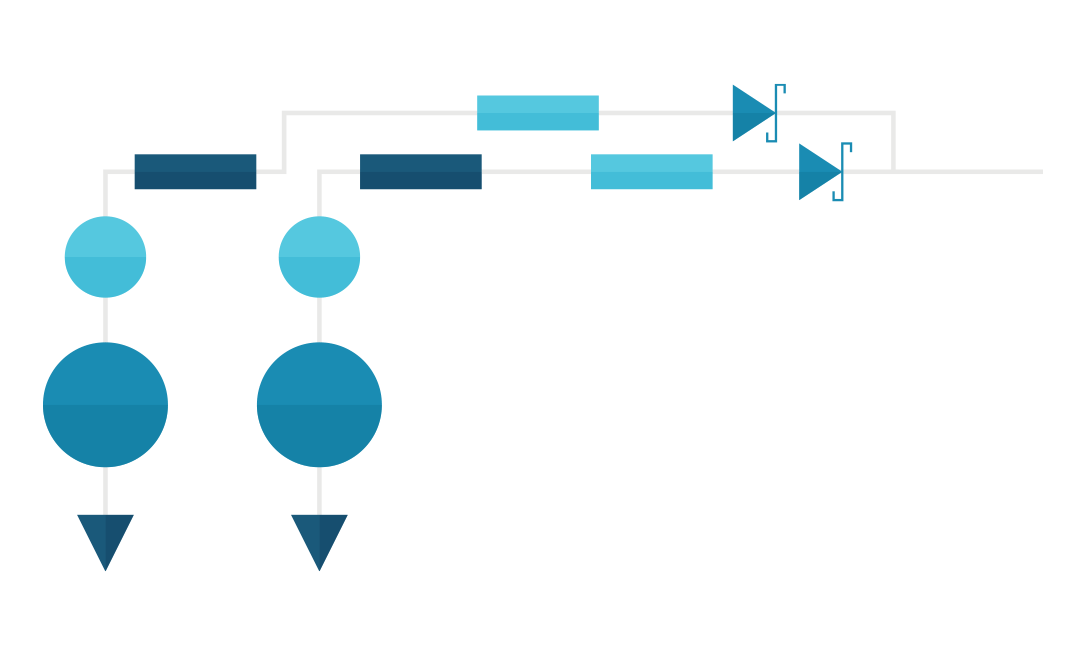

In some system designs the reliability of the power delivery system is important. Two topologies to increase system reliability are either connecting power supplies to operate in parallel or operating multiple power supplies in a redundant configuration. In this article we will discuss the reliability of power supplies operated in parallel and in a second article we will discuss redundant power delivery systems. The reliability of a power delivery system can be affected when the outputs of multiple supplies are connected in parallel to increase the power delivery to a system load.

The blog Connecting Power Supplies in Parallel or Series for Increased Output Power provides an introduction to the concepts of using multiple power supplies to provide the required power for a system. As is discussed in the article, designers typically connect the outputs of power supplies in parallel to increase the power available for the load. In this article we will discuss how the reliability of the power delivery system may be affected by using multiple power supplies.

Parallel Power Supplies

While configuring power supplies in a parallel configuration will increase the available output power level, it may either increase or decrease the reliability of the power system. The change in the reliability of the power delivery system due to connecting power supplies in parallel cannot be generalized because it is dependent upon the design of the system and the characteristics of the individual power supplies.

Failure Rates

We will start by discussing what we mean by the term “failure rate” and then look at how this term is applied to components, and then to systems comprised of components. A failure rate is a statistical value that describes the occurrence of failures within a defined period.

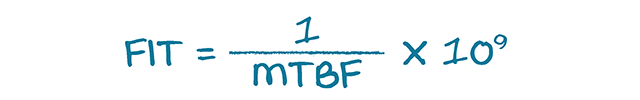

A common failure rate applied to reliability calculations for electronic products is FIT (Failure In Time) and it is the number of failures that are expected to occur in one billion (109) hours of operation.

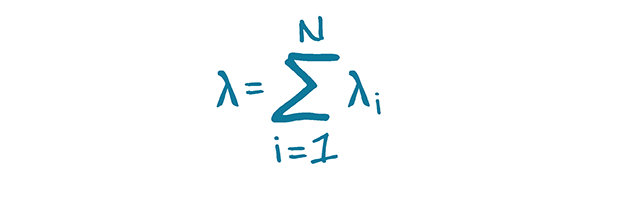

One method to calculate the failure rate (FIT) of a system is to calculate the FIT of each component in the system and then the system FIT can be calculated by adding up the values of the FIT for every component in the system.

Calculating the Failure Rate of a System

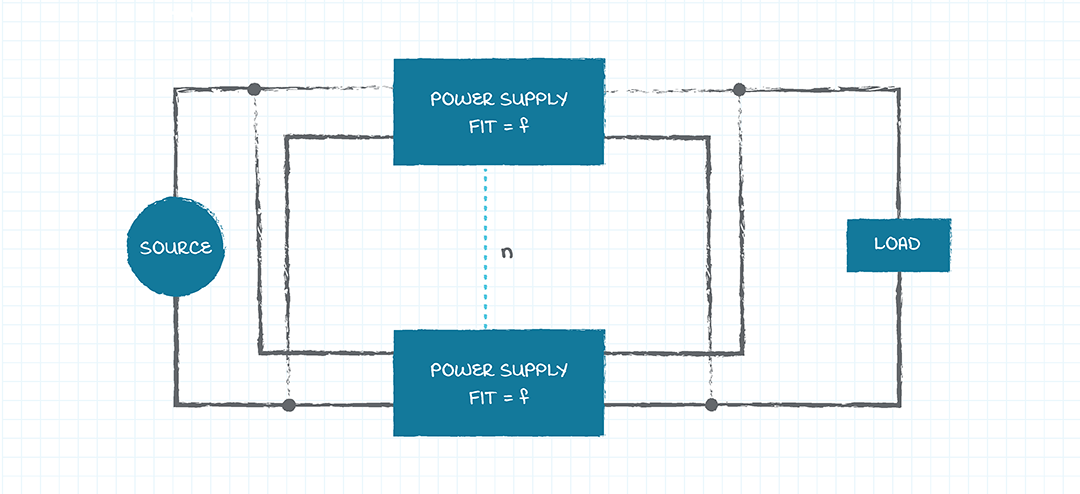

For a system comprised of n components, each with a FIT of f, the system FIT is n*f. It should be noted that a larger value of FIT is a less reliable system, more failures in a specific time.

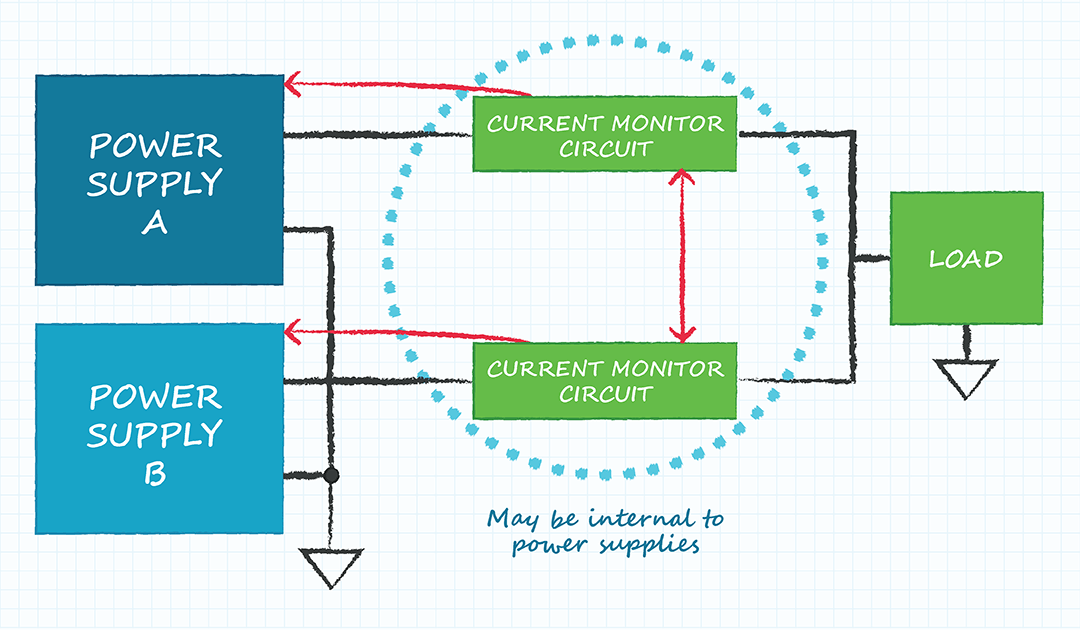

Applying the last statement to power supplies with the outputs connected in parallel, it suggests that the system failure rate may increase (reliability decrease) as the number of supplies increases. Some methods that the failure of a single power supply in a bank of paralleled supplies can lead to a failure of the power delivery system are as follows.

If the system is designed with n supplies connected in parallel and all the power supplies are necessary to provide the power required by the load, then if one power supply fails the others will not be able to provide the required output power and the power delivery system will fail.

Another method for a single power supply to cause the failure of multiple power supplies connected in parallel is if a power supply fails with the output shorted. The shorted output will cause the power delivery system to fail, even if the remaining supplies could have provided the required output power.

Whether employing multiple power supplies with the outputs connected in parallel increases or decreases the system reliability depends upon the relative reliability of the supplies used in the different configurations. As the two examples below show, more information is required before the change in the power delivery system reliability due to multiple power supplies can be determined.

Example 1:

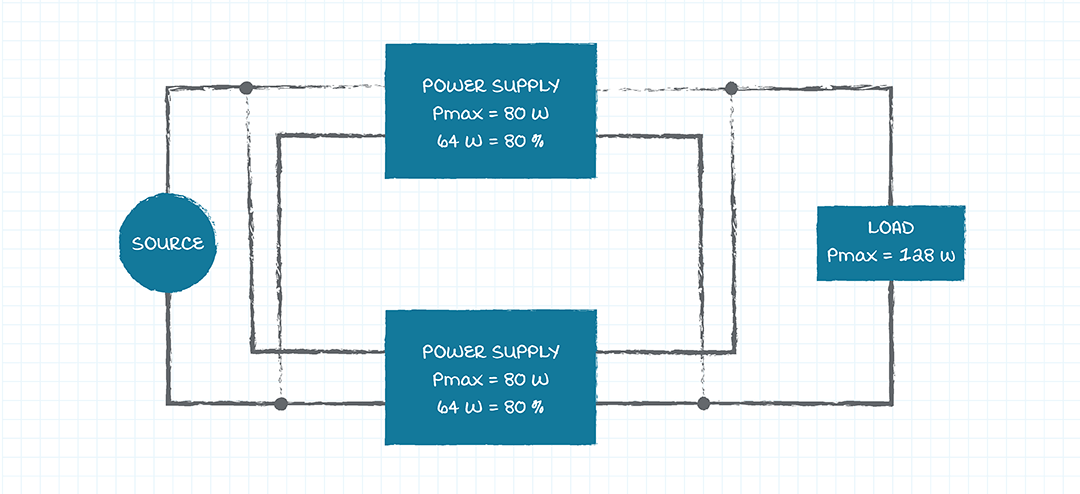

Design 1 – A system is designed where the total power delivery is required to be 128 W and two power supplies of 80 W output power will be used with the outputs of the supplies connected in parallel. In practice, the load current sharing will not be exact, but for purposes of analysis we will assume that each supply will be providing 64 W of output power (80% of rated output power) at 128 W system load power.

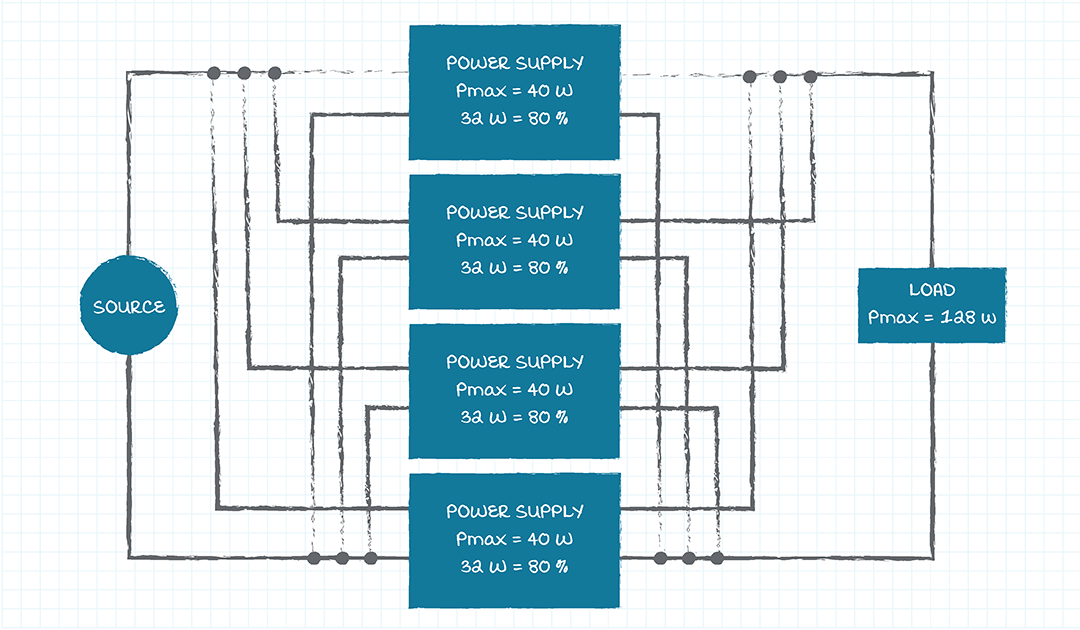

Design 2 – As a second alternative, four supplies with 40 W output power could be selected and in this design each supply would provide 32 W of output power and would again be operating at 80% of the rated output power. It may be reasonable to assume that if the designs of the 80 W and 40 W power supplies are similar, then the FIT for both designs will be similar when they are operated under similar conditions (percentage of rated power, ambient temperature, airflow, etc.).

With this set of assumptions, the power supply section of the system in design one with two power supplies in parallel will be more reliable, half the FIT (twice the reliability) as the system in design 2 with four power supplies in parallel.

- Design 1 FIT: 2-power supply topology with each power supply having FIT = f; system FIT = 2*f

- Design 2 FIT: 4-power supply topology with each power supply having FIT = f; system FIT = 4*f

The calculations above assume that the power supplies are selected such that the FIT of each supply remains constant as the number of supplies in the system increases. If the system has a fixed load and the same supplies are used as the number of supplies in the system are increased, then each supply will operate at a lower load current as more supplies are added.

For many power supply designs the FIT decreases (the supplies are more reliable) as they are operated at lower output power levels. Thus, increasing the number of power supplies placed in parallel will decrease the system FIT (increase the system reliability) if the FIT for each supply reduces faster than the sum of the FITs increases.

Example 2:

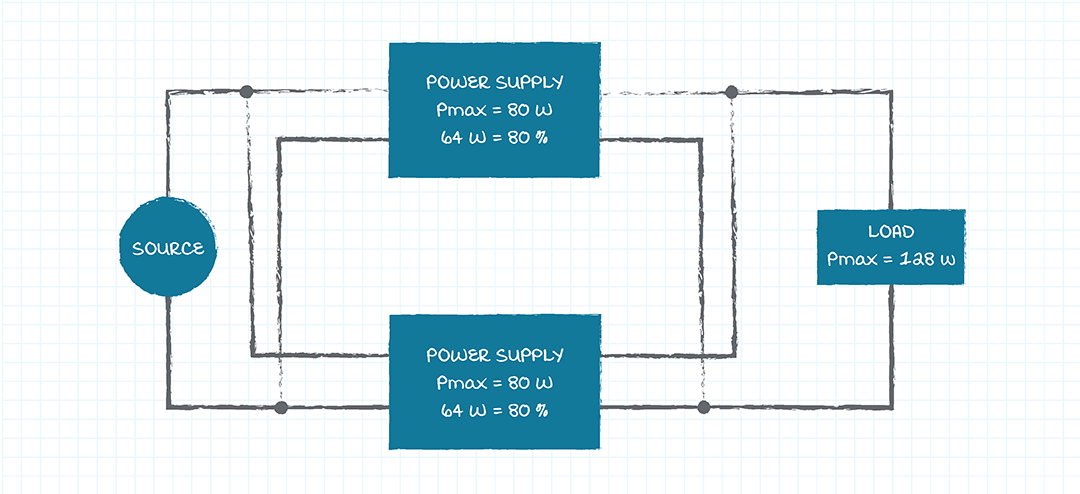

Design 1 – In this second example, the same 128 W system load is used and the same initial design of two power supplies rated at 80 W each is evaluated. The power supply system FIT (and reliability) will be the same as the first design in the first example.

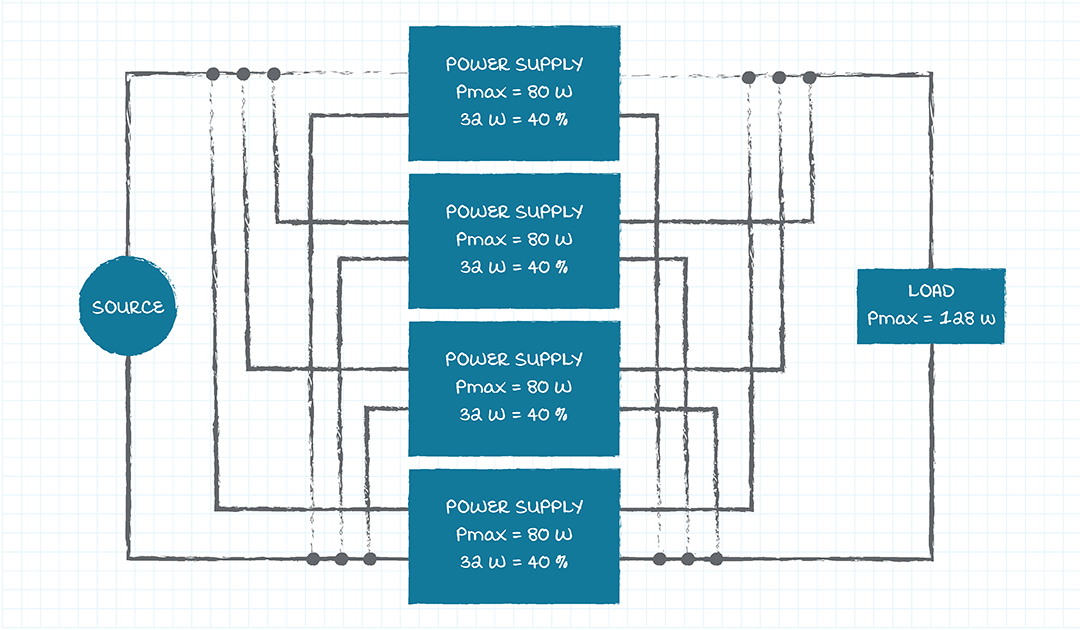

Design 2 – If a design incorporating four of the 80 W power supplies is selected, then each supply will be delivering 32 W and thus operating at 40% of rated power.

This is where generalizations no longer apply, and assumptions should be verified. If the FIT of the power supply operating at 40% of maximum power is less than half of the FIT at 80% of maximum power, then the reliability of the power delivery system is increased by using four power supplies rather than two power supplies.

- Design 1 FIT: 2-power supply topology with each power supply having FIT = f2; system FIT = 2*f2

- Design 2 FIT: 4-power supply topology with each power supply having FIT = f4; system FIT = 4*f4

- Additional information is required to determine which configuration has greater reliability

Summary

It is a common practice to parallel the outputs of power supplies to increase the power delivered to the load. In many of these configurations the failure of any one supply will cause the failure of the entire power delivery network. If the reliability of the power delivery network is desired to be known, it will be necessary to understand the effectiveness of the load current balancing and the reliability of the individual supplies under the operating conditions.

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com