Powering the Smart Revolution at 277 Vac: Enabling New Applications with Wide Input Power Supplies

July 27, 2021 by Ron Stull -

4 Minute Read

Last updated June 18, 2024

Introduction

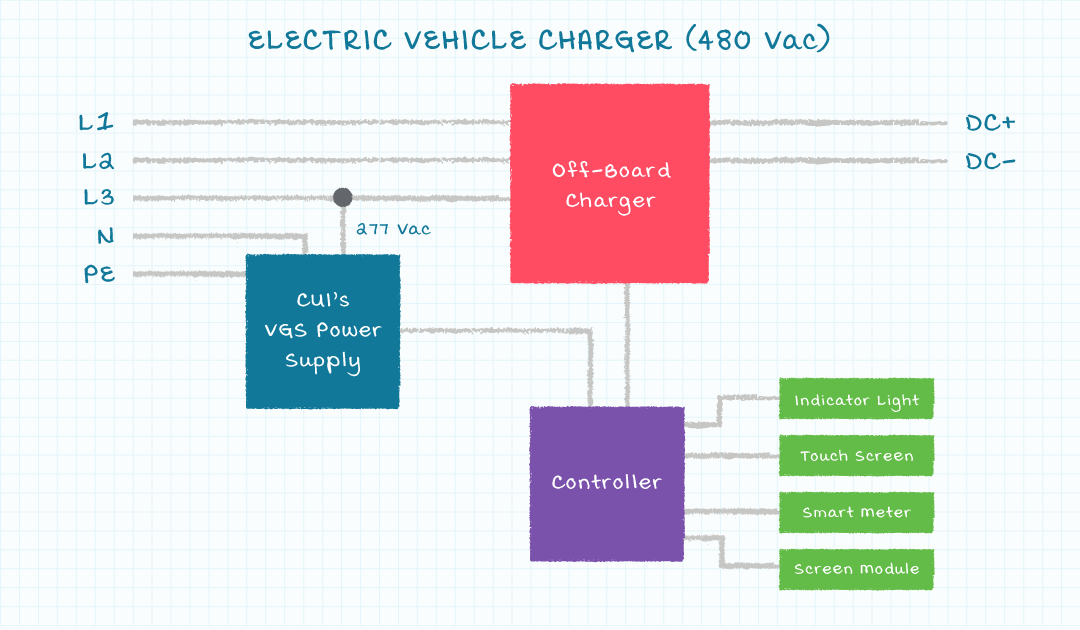

Widespread deployments of smart systems in out-of-home locations, as well as high-power applications such as roadside vehicle chargers, is driving easier access to ac-dc power supplies capable of handling a 277 Vac input derived from the standard 480 V three-phase industrial supply.

As consumers we mostly use appliances that are designed to plug into the 120 Vac domestic line, whereas utilities provide services at several voltages for different types of users and applications. Houses and other premises can have access to a 240 V service for large loads, while a 480 V three-phase supply is available for industrial uses. The phases are often used together to supply large loads, typically high-power electric motors used in industrial machinery.

480 Vac Advantages

Distributing power at 480 V delivers several advantages. The current is lower, for a given power demand, resulting in lower I2R losses in the line. In addition, cabling can have a lower current rating, saving cost as well as bulk in the distribution infrastructure. At the same time, the higher voltage allows greater capacity to connect more loads on the same line.

Where Does 277 Vac Come From?

Single-phase power can be taken from this 480 V three-phase supply by connecting between one phase and neutral. In this case, the nominal supply voltage is 480 V ÷ √3, or 277 V. Three separate circuits can be supplied this way, allowing a convenient and cost-effective means of powering various loads. This approach is commonly used to power fluorescent lighting circuits in industrial and commercial premises.

277 Vac Applications

With the adoption of low-energy LED lighting in factories, warehouses, offices, shopping malls, and street lighting, demand grew for constant-current LED drivers (suitable for connection to the 277 Vac supply and for generating a constant-current output for driving the LEDs). Things are changing now that the smart revolution is driving intelligent “things” into out-of-home locations. Examples include sensors and controllers for equipment installed throughout smart cities, including smart signage and security systems. Demand is also growing for high-power applications such as roadside fast charging of electric vehicles, municipal e-mobility schemes such as e-bikes and scooters, and for charging industrial electric vehicles like forklifts.

As with earlier fluorescent and LED lighting challenges, taking a 277 V single-phase supply from the 480 V three-phase service enables a convenient and cost-effective solution. What’s different with the smart revolution is that many of these loads contain electronics modules that need to be powered from a regulated dc voltage. As a result, demand is growing for ac-dc power supplies that can connect to a 277 Vac input and produce common dc output voltages.

10% Headroom and 305 Vac Rating

To be able to handle a nominal 277 Vac input voltage, with 10 percent safety headroom, the power supply must be capable of withstanding up to 305 V at the input. As a result, you will see a growing number of ac-dc power supplies in the market that offer a universal ac input voltage range from 85 V to 305 V. There is a broad choice of regulated output voltages and various options are available.

Additional Industrial Power Supply Features

Power supplies offering the wider ac input voltage rating of 85 ~ 305 with a regulated dc output provide flexibility for industrial and commercial power applications. Along with a wide input voltage range, other features that may prove beneficial in an industrial environment are:

- Terminal Covers and Conformal Coating: Stand up to harsh environments that may contain conductive debris or large quantities of dust as in sawmills or quarries, or for equipment deployed outdoors.

- Input Over Voltage Category III: Increased transient immunity to withstand large power surges. Learn More.

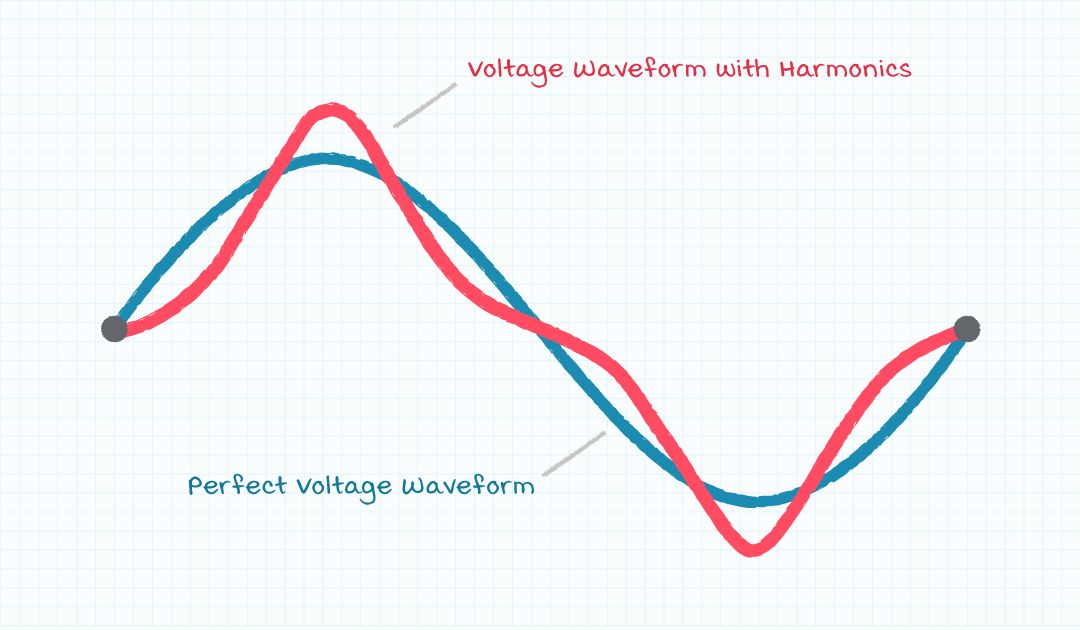

- Power-factor Correction: Reduce ac current and cable losses by utilizing active power factor correction to improve the active power to apparent power ratio. Learn More.

- Safety Standards: IEC 62368-1 for audio visual and information technology equipment and IEC 61558 for power supplies and transformers. Learn More.

Conclusion

Having a versatile selection of 85 ~ 305 V ac-dc power supplies available is useful to designers of IoT and IIoT equipment, installers, maintenance managers and purchasers who can now benefit from changes in the market, allowing them to quickly discover a suitable unit, off the shelf, to meet their exact needs. CUI offers an array of wide input range ac-dc internal power supplies, including low no-load power consumption options in the VGS family of metal-case SMPS and the PSK family of encapsulated power modules.

Industry News , Product Selection

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com